From time to time I work with start-up entrepreneurs developing or marketing new food products or major food manufacturers. I know a number of folks in the bottling business for everything from salad dressings to barbecue sauce. I didn't know how important it was to have the right label construction for your food product until recently. A number of months ago I presented at the Rutgers Food Innovation Center and there met Leslie Gurland of Logo-Tech. Her company specializes in label design and construction technical advice as well as production of pressure sensitive lables on an HP Indigo Press in New Jersey. Leslie shared the following information that I thought might be helpful to some of my readers and clients.

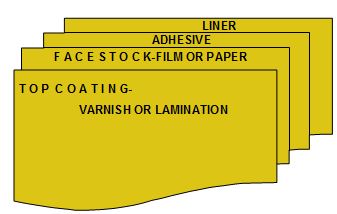

Each label is technically designed and layered with the right materials to stand up to the environment the label is working in. From manufacturing to distribution to retail a label has many factors including light, heat, humidity, and pressure that affect it's performance. A professional compelling marketing message must reach the shelf intact for maximum appeal and opportunities with customers.

Have the following questions answered before you speak with your label supplier to ensure a successful food labeling project.

1. What is the Container Construction? >Glass, PP, PET

The type of container will have various implications on how a label will adhere.

2. What is the Container Shape

Make sure you know the actual shape description from the manufacturer

3. Have you requested a label company create a die-line for your graphic artist

This is important to ensure your marketing message looks like you want it to. Your proof may look great, but in reality your words or images may wrap around the contour in a counter productive fashion. Make sure your designer understands where they can "design."

4. What are the Filling Conditions?

Speak with your co-packer or document conditions yourself. Be as exact as possible.

What is the Temperature, Time, & Humidity of the process?

5. Will the label be affixed through speed machine application or hand filling?

6. What will Transportation Conditions be like? > Handling, Temperature,

Humidity Think forward as well. Right now product may be delivered from the trunk of your Honda Accord, but in 6 months you might land a big contract and want the labels to work accordingly with boxed and palletized shipments on a tractor trailer across country.

7. What are the Retail Conditions>Handling, Temperature, Humidity

8. Will label supplier provide die blanks?

Make the request, any information or exactness you have will help for a better end product.

9. Who is my customer?

The most important part of your label's performance (after we know it's going to stay on the bottle is the marketing message and visual. It is important to work with industry designers who can coach you on how food sells. Just because your brother-in-law knows photoshop or illustrator it doesn't qualify them to design a food label.

Stay tuned for more labeling ideas.

Have the following questions answered before you speak with your label supplier to ensure a successful food labeling project.

1. What is the Container Construction? >Glass, PP, PET

The type of container will have various implications on how a label will adhere.

2. What is the Container Shape

Make sure you know the actual shape description from the manufacturer

3. Have you requested a label company create a die-line for your graphic artist

This is important to ensure your marketing message looks like you want it to. Your proof may look great, but in reality your words or images may wrap around the contour in a counter productive fashion. Make sure your designer understands where they can "design."

4. What are the Filling Conditions?

Speak with your co-packer or document conditions yourself. Be as exact as possible.

What is the Temperature, Time, & Humidity of the process?

5. Will the label be affixed through speed machine application or hand filling?

6. What will Transportation Conditions be like? > Handling, Temperature,

Humidity Think forward as well. Right now product may be delivered from the trunk of your Honda Accord, but in 6 months you might land a big contract and want the labels to work accordingly with boxed and palletized shipments on a tractor trailer across country.

7. What are the Retail Conditions>Handling, Temperature, Humidity

8. Will label supplier provide die blanks?

Make the request, any information or exactness you have will help for a better end product.

9. Who is my customer?

The most important part of your label's performance (after we know it's going to stay on the bottle is the marketing message and visual. It is important to work with industry designers who can coach you on how food sells. Just because your brother-in-law knows photoshop or illustrator it doesn't qualify them to design a food label.

Stay tuned for more labeling ideas.

RSS Feed

RSS Feed